Plastic spraying on stainless steel plates is a surface treatment technology that improves the aesthetics, corrosion resistance and wear resistance of stainless steel by spraying a plastic coating on the surface of stainless steel. The specific steps of plastic spraying are as follows:

1. Surface cleaning and pretreatment

Before plastic spraying, the surface of the stainless steel plate must be thoroughly cleaned and pretreated to ensure good adhesion of the coating to the metal surface.

Remove oil stains: Use solvents or detergents to remove impurities such as grease and stains on the surface of stainless steel.

Remove oxide scale: If there is an oxide layer or rust on the surface of stainless steel, chemical agents or physical methods can be used to remove the oxide scale.

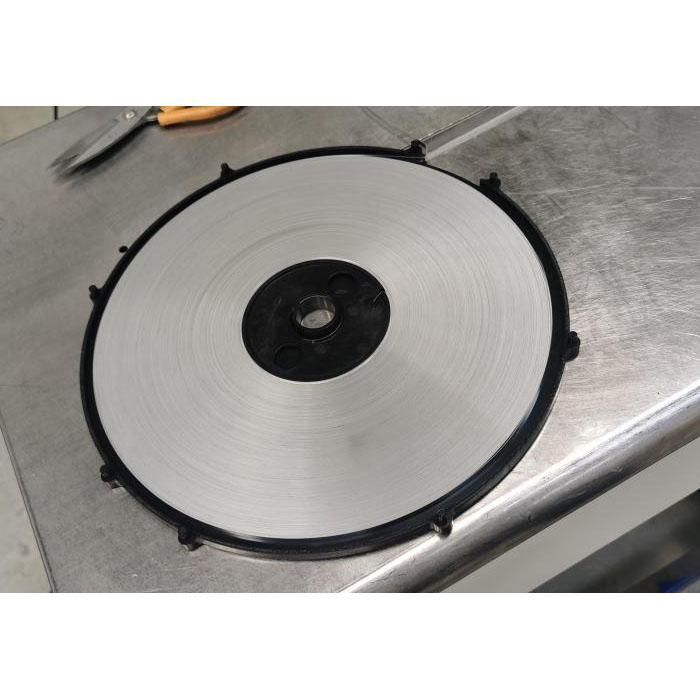

Surface grinding: Sandpaper or polishing equipment can be used to grind the surface of stainless steel to make the surface smoother and enhance the adhesion of the spray coating.

Pickling: If there are too many oxides on the surface, pickling can be carried out with pickling liquid to clean the surface and remove impurities on the metal surface.

Surface roughening: Fine textures are created on the surface of stainless steel by sandblasting or using special roughening agents to enhance the adhesion of the plastic coating.

2. Primer treatment

Primer: In order to enhance the adhesion of the spray coating and prevent rust or blistering on the surface, a layer of primer is usually applied to the surface of the stainless steel plate. The choice of primer depends on the spray material and the use environment. Common ones include epoxy primer or polyester primer.

3. Spray plastic coating

Select spray material: Common materials for stainless steel spray are polyester, fluorocarbon, epoxy, etc. Different plastic coatings have different weather resistance, chemical resistance and aesthetic effects. Choose the appropriate spray material according to your needs.

Spraying method: Electrostatic spraying or thermal spraying methods are usually used.

Electrostatic spraying: Plastic powder is adsorbed on the surface of stainless steel by electrostatic force to form a uniform coating. When spraying, the powder coating will be accelerated by the electrostatic force of the electric spray gun and evenly sprayed on the stainless steel surface.

Liquid spraying: Use liquid plastic coating (such as fluorocarbon paint, epoxy paint, etc.) for spraying, and spray it on the stainless steel surface through a spray gun.

When spraying, ensure that the thickness of the spray is uniform and avoid too thick or too thin coating.

4. Baking and curing

Baking treatment: After spraying, the stainless steel plate needs to be sent to the oven for curing. The common baking temperature range is 180°C-220°C, and the baking time is generally 10-20 minutes. Through heating, the plastic coating will solidify and bond tightly to the stainless steel surface to form a solid coating.

Curing effect: Ensure that the coating is fully cured and has good adhesion, wear resistance and weather resistance.

5. Cooling and post-processing

Natural cooling: After spraying and baking, the stainless steel plate needs to be cooled naturally to avoid thermal expansion and contraction affecting the quality of the coating.

Post-processing inspection: After cooling, the stainless steel plate needs to check whether the adhesion, flatness, thickness, etc. of the coating meet the standards. For unqualified parts, re-spraying or repair may be required.

6. Quality inspection

After spraying, the quality of the coating needs to be inspected. Common inspection items include:

Adhesion test: Check whether the spray coating is firmly attached to the stainless steel surface, which can be tested by cross-cutting method, tensile test, etc.

Coating thickness: Use a coating thickness gauge to check the thickness of the coating to ensure that it meets the requirements.

Appearance inspection: Check whether the coating is uniform and smooth, and whether there are defects such as bubbles and peeling.

Corrosion resistance test: Perform salt spray test on the coating to ensure that the coating has sufficient corrosion resistance in harsh environments.

In summary, the surface spraying treatment of stainless steel plates is to spray the plastic coating evenly on the surface of the stainless steel plate through multiple steps such as cleaning, priming, spraying, and baking, thereby improving its corrosion resistance, wear resistance and aesthetics. When performing spraying treatment, pay attention to factors such as surface treatment, spraying method, and coating thickness to ensure that the coating quality meets the actual application requirements.